What is gravity separation

Gravity separation

All of the gravitational methods are common in the sense that they all use gravity as the dominant force. In the moving medium (water, air and heavy liquid), mineral particles with different densities are affected by hydrodynamic forces and various mechanical forces, resulting in suitable conditions for loose stratification and separation, so that particles with different densities can be separated.

Advantage of gravity separation

The most notable advantages of the gravitational methods are their cost effectiveness and in some cases excellent reduction. Gravity separation is an attractive unit operation as it generally has low capital and operating costs, uses few if any chemicals that might cause environmental concerns and the recent development of new equipment enhances the range of separations possible.

Application in mining

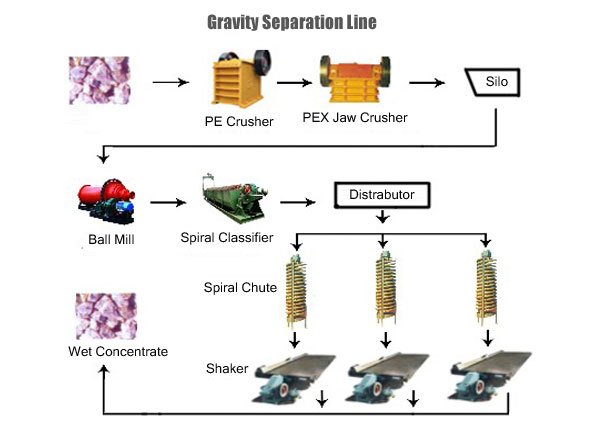

Gravity separation is the main method for separating rock gold, alluvial gold, wolframite, cassiterite, coarse iron and manganese ore. It is also widely used in the separation of rare metal placer.The size range is wide, ranging from a few hundred millimeters to less than one millimeter.Where the mineral particle size in the above range and between the components of the specific gravity difference is large, with the most appropriate gravity selection. Sometimes, it can be used to preselect and remove part of the waste rock by gravity separation (mainly gravity medium separation, jigging, etc.), and then be treated by other methods to reduce the dressing cost.

Types of gravity separators

With the increase of lean ore and fine raw mineral materials, in order to improve the gravity separation efficiency of fine material, gravity separation equipment tends to be larger and multi-layer, and the use of complex motion equipment, such as centrifugal concentrator, shaking table, sprial chute, jig machine etc., Now it is possible to select 20 μm material efficiently.

For more details of gravity separator please click here.