Chrome Ore process plant

We supply full line of mining equipments and technical support

Chrome Ore process plant

Hengcheng offers turnkey solutions for Chrome Washing/Beneficiating Plant. We are one of the leading project suppliers for Chrome Ore Washing/Separating Equipment and we work closely with our customers to fulfill their specific needs for customized package solution. Specialized in the fabrication of these machines for 20 years and this enables us to be in a leading position in the field of Chrome Ore Washing.

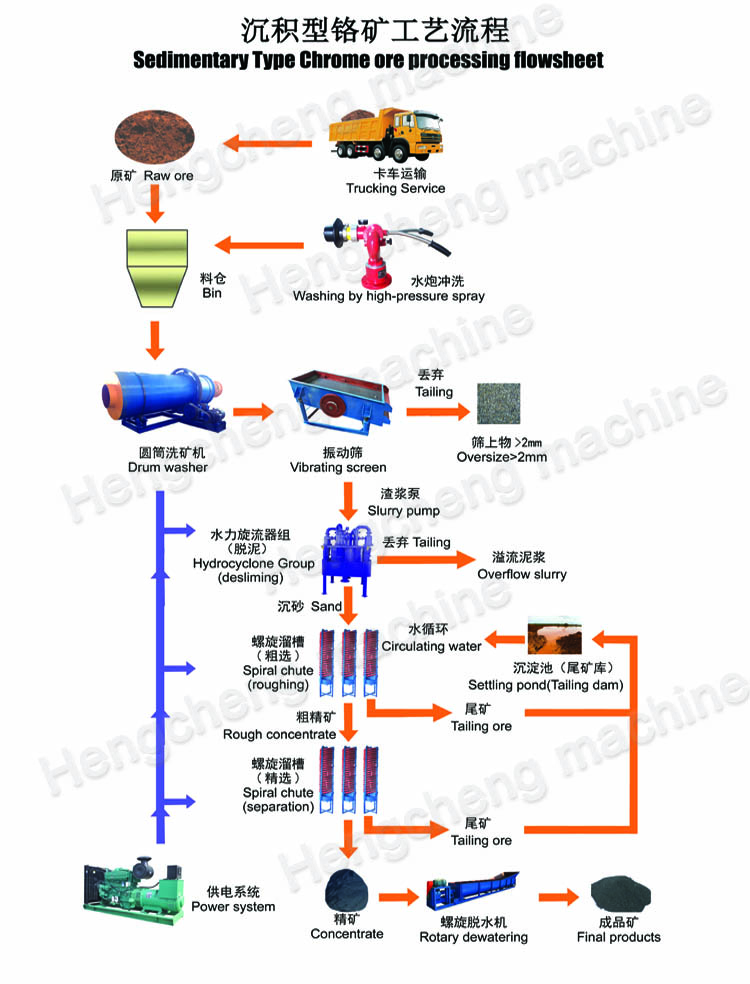

Scope of Supply for sedimentary chrome washing plant

We can supply the whole line of Chrome ore washing plant, including:

1. trommel screen / vibrating screen / rotary scrubber, etc

2. spiral chutes

3. hydrocyclones

4. slurry pumps

5. water pump & diesel generator

6. electric control panel & cables

7. New or Used loader / excavator

Detailed Machinery Information

Machine Pictures | Brief Description |

| |

|

|

| |

| |

|

|

| |

| |

| |

|

|

Spiral Chute Introduction:

Spiral chutes are gravity concentrators and separate minerals of different specific gravity according to their relative movement in response to gravity,centrifugal force and other forces in the fluid medium.It has extremely good performance and effects in processing placer of beach, riverside, seashore and stream.

Our Spirals are made of polyurethane lined fiber glass with wearable corundum inner surface.

Generally there are 5 turns in one start, single, twin, triple and quad starts available per column to suit capacity requirements.

Previous Chrome Ore Washing Plant Projects Show:

Chrome ore washing plant rotary scrubber & vibrating screen

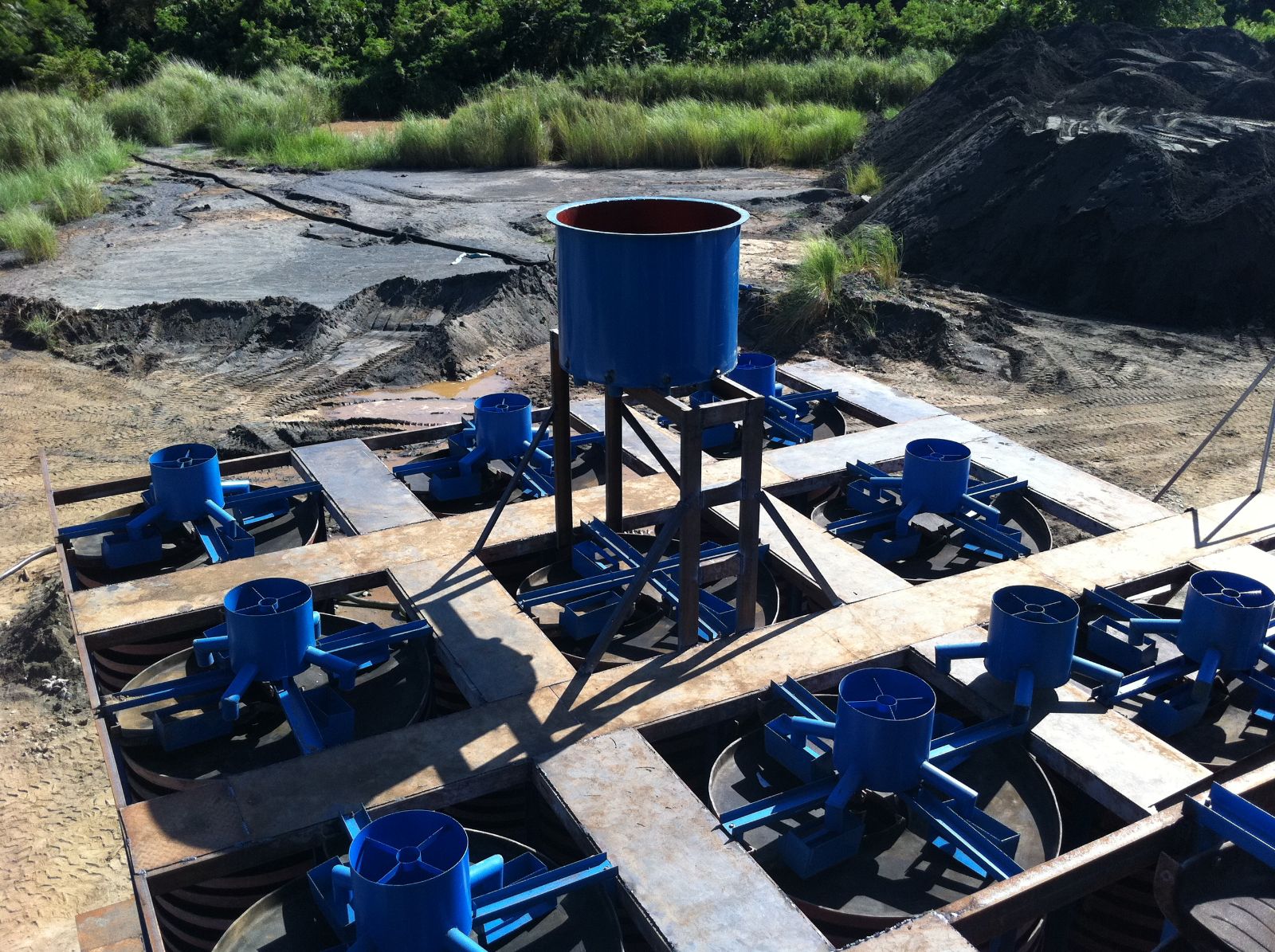

Hydrocyclone cluster for mud&soil removing

Several stages of Spiral chutes for chrome ore separation

Final chrome ore concentrate powder ( reach grade 40%-45%)

Spiral Chutes Working Video Link:

http://v.youku.com/v_show/id_XNzQzODk5MzQw.html

More than a chrome ore washing plant supplier:

At Hengcheng, we provide more than just chrome ore washing/separating equipment, but constantly strive to assist you in achieving overall business excellence. This is why when you partner with Hengcheng, you don’t just get a diversified product offering, but form a relationship based on product refinement, a true understanding of gold process flow sheets and field service and maintenance ---ensuring that together we will create a solution that is suited specifically to your individual needs and that will optimize your process and lower your overall operating costs.

Welcome to contact for further discussion.

Ms Tina Xu / Sales Manager

Mob: 0086-19907910905 (whatsapp)

Email: wendy@oreshaker.com

- 相关新闻

.jpg)

.JPG)