Alluvial diamond mining equipment

Where is the diamond from?

In mining, diamonds are recovered mainly from alluvial deposits which vary widely in character, often cemented. And usually contain large quantities of clay or a sticky slime fraction from near zero to about 50% substantial production also comes from Kimberlite pipes and dikes, a basic igneous breccia, considered generally to be the originating source for nearly all diamonds.

Since the value per ton of diamondiferous gravel seldom exceeds one metric carat per ton with an average of fewer than 0.3 carats, a high ratio of concentration, in the order of 1:5,000,000 or higher, is necessary.

Alluvial diamond mining equipment / 90%+ diamond Recovery Ratio

Hengcheng offers turnkey solutions for Alluvial diamond mining equipment. We are one of the leading project suppliers for Alluvial diamond mining equipment Equipment and we work closely with our customers to fulfill their specific needs for customized package solution. Specialized in the fabrication of these machines for 20+ years and this enables us to be in a leading position in the field of Alluvial diamond Washing.

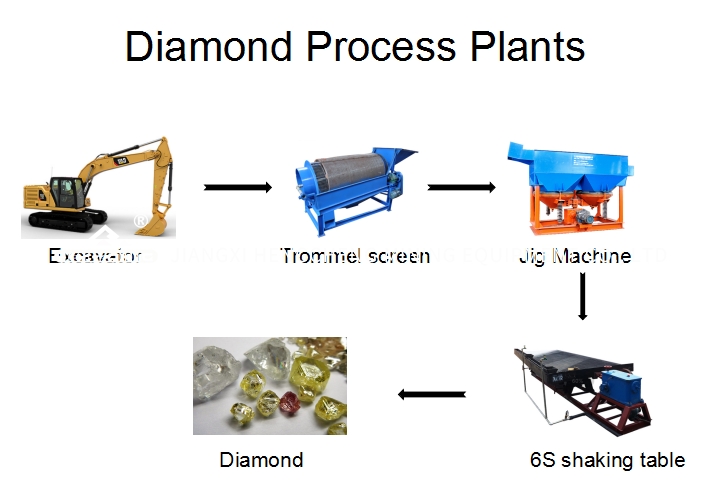

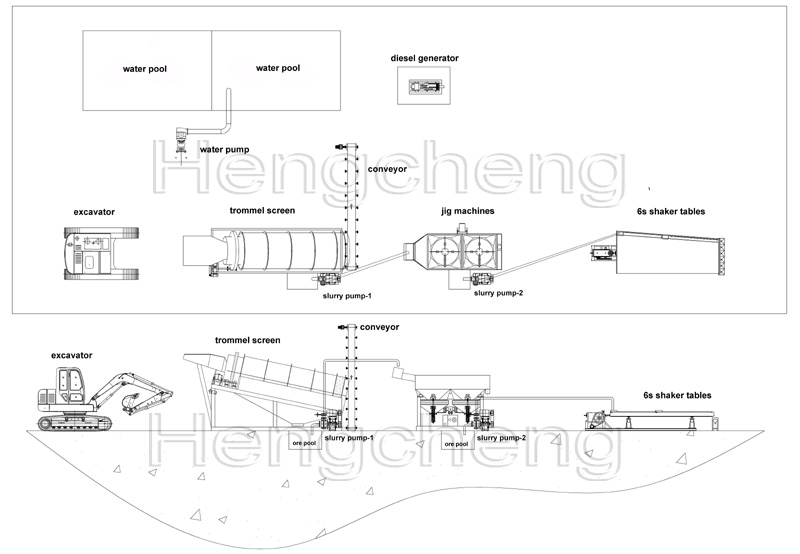

General alluvial diamond mining equipment flow sheet design:

Scope of Supply

We can supply the whole line of diamond mining equipment, including:

1. Trommel wash plant, vibrating screen,etc

2. jig machine

3. 6S shaking table

4. excavator / bull loader

5. water pump & diesel generator

6. electric control panel & cables

Vary Processing Amount Machinery List

diamond mining equipment Machines List | ||||

ITEM | MODEL | QTY | MOTOR (KW) | WATER (m3/h) |

20TPH | Trommel wash plant/ GT1015 | 1 set | 4.0 | 70-80.0 |

JT2-2 | 1 set | 3.0 | ||

2 sets | 1.1*2 | |||

50TPH | Trommel wash plant/ GT1545 | 1 set | 15.0 | 180-200.0 |

Jig machine/ JT5-2 | 2 sets | 7.5*2 | ||

6S shaking table | 4 sets | 1.1*4 | ||

100TPH | Trommel wash plant/ GT1860 | 1 set | 22.0 | 420-450.0 |

Jig machine/ JT5-2 | 4 sets | 7.5*4 | ||

6S shaking table | 8 sets | 1.1*8 | ||

Detailed Machinery Information

Machine Pictures | Brief Description |

| 2. Brand: HENGCHENG 3. Function: to wash the feeding ore material, and screen out most part of big size useless material (normally >6.0mm). 4. Structure: 2 layers of screen + channel steel outframe |

| 1. Item: Saw-tooth wave jig machine 2. Brand: HENGCHENG 3. Function: as a rough separation&beneficiation machine to collect most part of heavy mineral, including diamond ore. and further removing useless small size material. its effective recover diamond particle down size could reach 200mesh. 4. Structure: steel plates+channel steel for outframe |

| 1. Item: 6S shaking table (4500mm) 2. Brand: HENGCHENG 3. Function: for final separation & extraction of diamond, to get high grade diamond-bearing concentrate ore. its effective diamond recovery down size could reach -74micron. 4. Structure: FRP deck + channel steel frame |

| 1. Item: diesel generator set 2. Brand: YUCHAI / CUMMINS,etc 3. Function: supply electric power for all machine motors 4. voltage: 380v/50hz/3phase |

| 1. Item: water pump 2. Brand: HENGCHENG 3. Function: supply water to Trommel wash plant, jig machines, shaking tables. |

| 1. Item: water flushing gun 2. Brand: HENGCHENG 3. Function: add water & flush the feeding ore, to help next step Trommel wash plant screening. |

Previous diamond mining equipment Projects Show:

Recovered diamond ore from customer's mine site by our machinery.

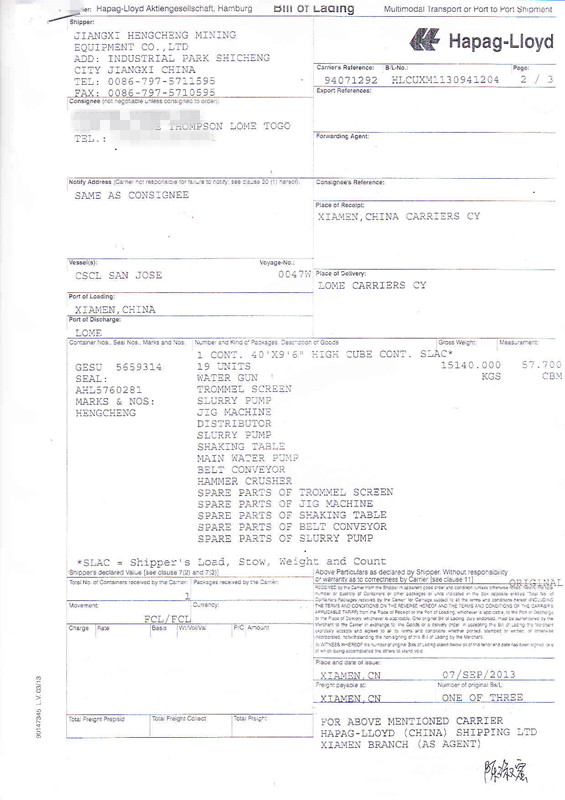

Small diamond wash plant in Africa Togo.

Mid-scale diamond mining equipment in Ghana-1.

Mid-scale diamond mining equipment in Ghana-2.

shaking table's separation performance.

shaking table's separation performance.

Alluvial diamond mining equipment B/L file for Africa customer

More than a diamond mining equipment supplier:

At Hengcheng, we provide more than just diamond washing equipment, but constantly strive to assist you in achieving overall business excellence. This is why when you partner with Hengcheng, you don’t just get a diversified product offering, but form a relationship based on product refinement, a true understanding of diamond process flow sheets and field service and maintenance ---ensuring that together we will create a solution that is suited specifically to your individual needs and that will optimize your process and lower your overall operating costs.

Welcome to contact for further discussion.

Ms Tina Xu / Sales Manager

Mob: 0086-19970910905 (whatsapp)

Email: sales@oreshaker.com

- 相关新闻